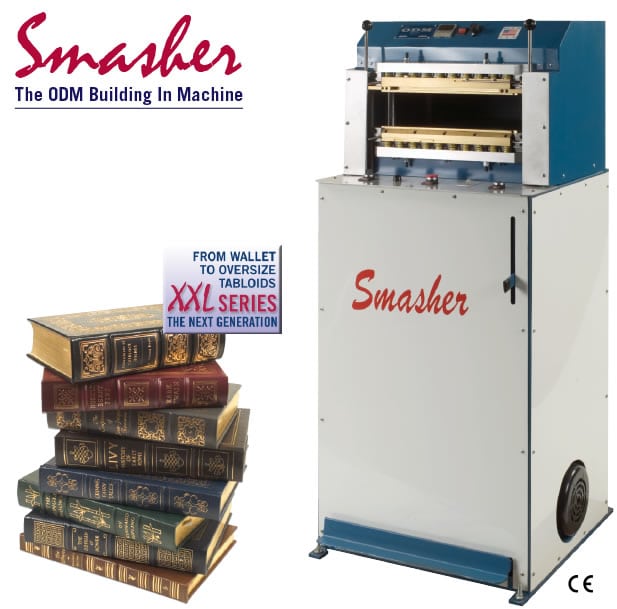

The Smasher is a self-adjusting hydraulic building in machine. The operator places the cased-in book into the Smasher and depresses a foot pedal that brings the top joint iron in contact with the book. This enables the operator to accurately find the joint area of the book. After locating the joint area, two buttons are depressed that activate the hydraulic system that raises the bottom steel platen and clamps the book with 20,000 pounds of pressure. The heated joint irons aid in forming the joint by reactivating the adhesive in the joint area and softening hard cover materials such as library buckram and film laminates. The Smasher has an adjustable dwell timer that controls how long the book remains under pressure. The heated joint irons have a thermostat for varying the degree of temperature.

STANDARD FEATURES:

• Easy to operate controls.

• Dual button operation insures operator safety.

• Ten tons of hydraulic pressure produces highly compressed books

• Adjustable dwell timer controls the amount of time the book remains under pressure.

• Thermostat control for heated joint irons aid in forming a perfect joint.

• Produce 150 to 240 books per hour.

Comments are closed.