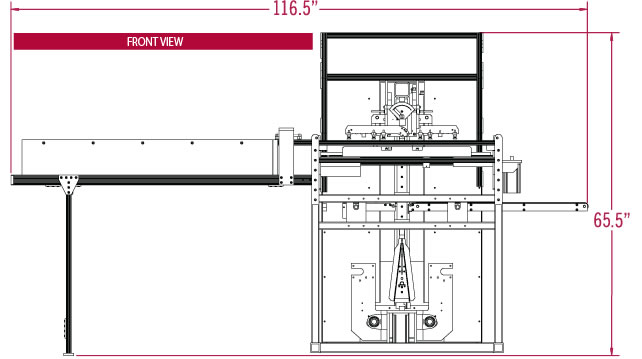

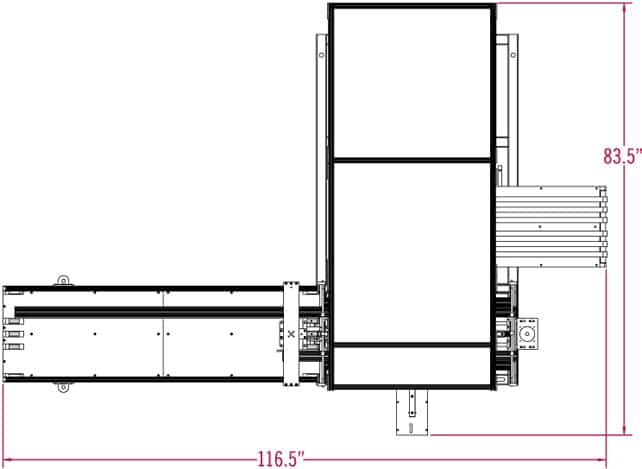

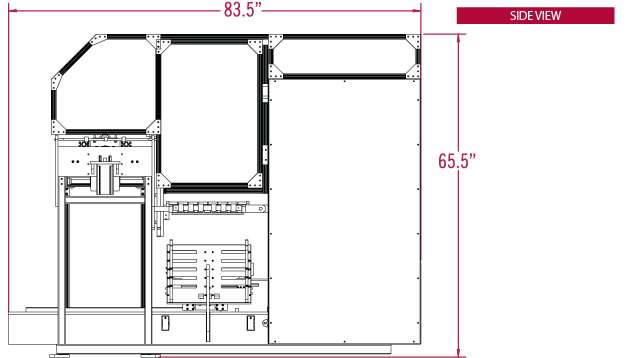

The Super Sticker™ can produce 400 to 600 books per hour.

Automated casing-in machine is designed for high volume, on demand binding operations. No special skills are required to operate this self-adjusting machine. Easy-to-use control panel allows the operator to format book size. Operator just places the sewn book block on the wing while the Super Sticker™ is in the home position. Book covers are placed on the left conveyor belt. Finished cased-in hard cover books are delivered on the right conveyor belt.

• No make-ready time is required.

• Multi-language touch screen LCD control panel allows the operator to choose settings in six different languages:

English, French, Spanish, Japanese, German and Italian.

• Touch screen computer controlled position of blade height.

• Glue stations are easily removed for a quick clean up.

OPTIONAL FEATURES:

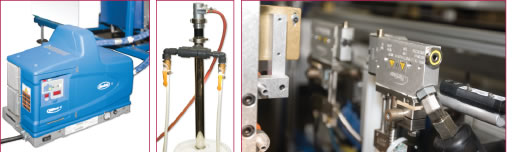

• Nordson extra paste attachment deposits additional hot melt adhesive in joint area.

• Auto-feed attachment is available for seamless assembly line production for Super Smasher™ building-in machine.

Optional Nordson hot melt attachment shown below conveyor belt.

Optional Nordson hot melt paste attachment for additional adhesive in the joint area is available with our standard equipment: Cold Adhesive Pump and Regulator and Electronic Controlled Nozzle Spray for Precise Application.

Standard LCD Touch Screen Control Panel

Comments are closed.